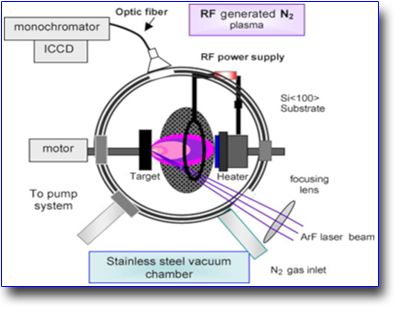

ns-PLD (@ 193 nm) in HV or reactive

gaseous atmosphere

Daniele M. Trucchi - daniele.trucchi@ism.cnr.it

DiaTHEMA Lab

TECHNICAL SPECIFICATIONS

-

high vacuum pressure <10; partial pressure with inert or reactive gases in the range 0.1 - 100 mbar< 10-7mbar; ;

-

excimer laser - ArF (Lambda PhysikCOMPex 102);

-

duration of the single impulse: 30 ns;

-

wavelength: 193 nm;

-

Repetition Rate: 1 - 20 Hz;

-

energy of the single pulse: 0 - 120 mJ;

-

-

rotating multi-target system with 3 possible slots;

-

substrate heating up to 800 ° C;

-

home-made system for micrometric handling of the substrate

-

target-substrate distance: 3-10 cm

-

possibility of carrying out plasma-assisted depositions using a 13.56 MHz RF generator (mod. Huttinger PFG 300, max. power 300 W)

AVAILABLE TECHNIQUES

- Pulsed Laser Deposition in HV or reactive atmosphere

SAMPLES

The mechanical integrity of the samples is required since they are mounted in a vertical position;

-

Sample size 4 x 4 cm2 (maximum), 1 x 1 cm2 (ideal);

USED FOR

-

Deposition of thin films of:

- Carbon based materials

- Semiconductors (e.g., AlN)

- thermoelectric and thermionic materials (e.g., PbTe, ZnSb)

- borides, carbides and oxides (e.g., WC)

- alloys

CASE STUDIES

Carbon nitride films by RF plasma assisted PLD: Spectroscopic and electronic analysis

- Carbon nitride (CN) thin filmsx) were grown on Si <100> by ns-ArF (193 nm) laser ablation on a pure graphite target, in a low pressure N2 plasma generated with RF, and were compared with samples grown with PLD in a pure nitrogen atmosphere.

See: E. Cappelli et al. Appl. Surf. Sci. 257 (2011) 5175-5180

ZnSb-based thin films prepared by ns-PLD for thermoelectric applications

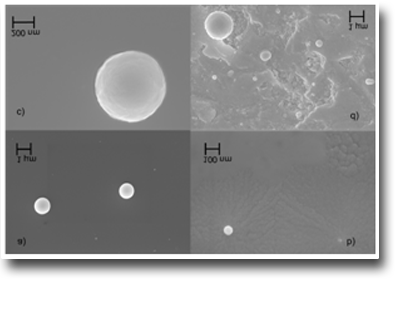

ZnSb-based nanostructured thin films were produced by Pulsed Laser Deposition (PLD) using an ns-ArF laser (193 nm) and a multi-target deposition system. The films were prepared following a multi-layer structure, obtained by adding different dopants (Cr, Ag) inside the ZnSb matrix.

See: A. Bellucci et al., Appl. Surf. Sci. 418 (2017) 589-593

English (UK)

English (UK)  Italiano (Italia)

Italiano (Italia)