Precision Mechanics ARTOV1

Fabrizio Corvasce - fabrizio.corvasce@ism.cnr.it

Roberto Scaccia - roberto.scaccia@ism.cnr.it

Workshop 0F12-13

The design and workshop facility Precision Mechanics ARTOV1 supports experimental activities for ISM and mechanical plants for Common Area Roma 2 Services.

TECHNICAL SPECIFICATIONS

Machine tools

- Parallel Lathe (model Graziano SAG 14)

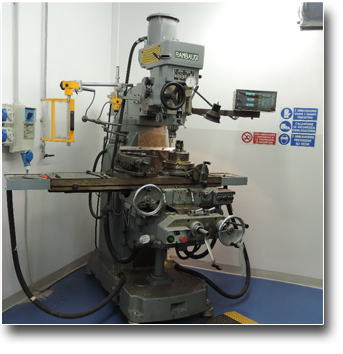

- Universal Milling Machine (model Rambaudi MG3)

- Drill Press (model Rosa - high speed)

- Circolar Saw (model Omes mec90)

- Abrasive wheels (various types)

- Metal Bandsaw (Friggi)

Metrology

- Cast Iron Surface Plate mm 1500x1020

Welding

- Wire Welders (Esab MeK 2)

- Welding machine (Miller 430A/BP-Cy50)

- Centrifugal extractor fan (Coral mod. no smoke)

- Oxy-acetylene Torch

AutoCAD workstation

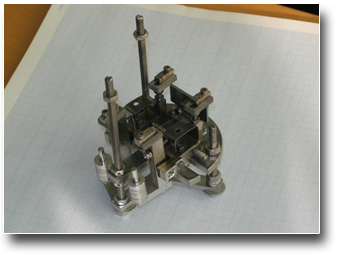

The main activity consists of CAD design and consequent construction of various types of mechanical components: sample holders, UHV fittings, optical fittings, prototypes, cryostat, setup, etc.

Support activities are also carried out for the Common Services of the Research Area of Rome 2, providing ordinary and extraordinary maintenance to mechanical systems.

SAMPLES

-

Bonding area: 3.75”x3.75” (95 mm x 95 mm), max.

-

Thickness device: 200 mil (5.1 mm)

USE FOR

-

Thermal bonding

CASE STUDIES

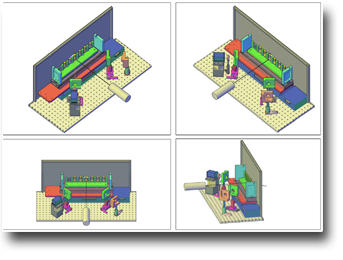

Neutron setup made for ISIS

Optical components

Hold sample for anelastic spettroscopy at HT

English (UK)

English (UK)  Italiano (Italia)

Italiano (Italia)