The Kulicke & Soffa mod. 4123 is an Al/Si and Au wire wedge bonder that can be used for bonding devices ranging from simple Integrated Circuits (ICs) and discrete devices up to complex hybrids with height variations up to 200 mils. The machine can operate in either thermosonic or ultrasonic mode.

TECHNICAL SPECIFICATIONS

Wire

- Diameter range: Al/Si 1.0 to 3.0 mils (25 to 75 μm), Au 0.5 to 3.0 mils (12 to 75 μm).

- Spool size: 0.5” (12.5 mm) diameter, 2.0” (50 mm) diameter (optional)

Performance

- Cycle time: 1500 ms (incl. 100 ms bond time)

- Bond force: 10 ÷ 160 g (range programmabile di 80 g)

- Bond time: 10 ÷ 100 ms o 100 ÷ 1000 ms

- Ultrasonic power (with 40 Ohm load): low 0.8 W (max.), high 2.8 (max.).

Mechanical

- Throat depth da 5.5” (140 mm)

- Wire trajectory: 30°/45° standard

- Reset to overtravel (range totale): 0.2” (5.1 mm)

- Table motion: 0.5” (12.7 mm) diametro

- Table load: 6 kg (max.)

- Bonding area: 3.75”x3.75” (95 mm x 95 mm), max

- Chessman ratio: 6:1

- Tail length modificabile

Thermocouple controller

- Thermocouple input: type J (Iron-Constant)

- Indicating range: 0 – 400 °C

- Set point range: 50÷400°C

- Zero offset: ± 45 °C di variazione totale

- Accuracy: 0.5% of full scale @25 °C

- Operating temperature: 0÷50°C

- Cold junction compensation: 0 – 50 °C @25 °C

AVAILABLE TECHNIQUES

- Optical lithography

- Spin coating

SAMPLES

-

Bonding area: 3.75”x3.75” (95 mm x 95 mm), max.

-

Device thickness: 200 mil (5.1 mm)

USE FOR

- Ultrasonic wedge bonding

- Thermosonic wedge bonding

CASE STUDIES

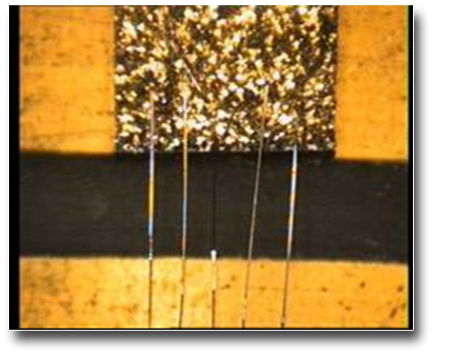

Diamond single pixel detector for X-rays

It is a metal-semiconductor-metal photoconductive structure. Bottom contact (not shown) is glued to the PCB by conductive silver paste. Top contact is wire-bonded with up to 5 Al/Si wires to ensure mechanical robustness.

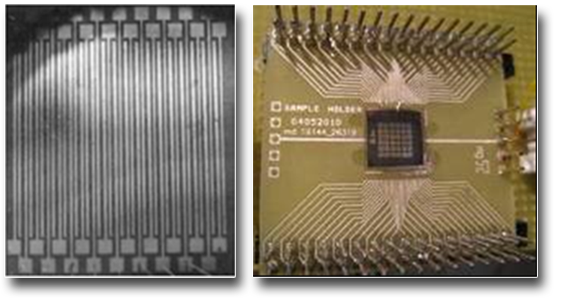

Diamond multipixel detectors for UV and X-ray source imaging

See: M. Girolami et al., IEEE Electron Device Lett. 33 (2012) 224-226

English (UK)

English (UK)  Italiano (Italia)

Italiano (Italia)