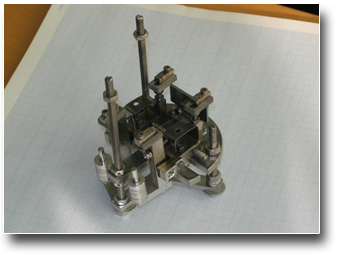

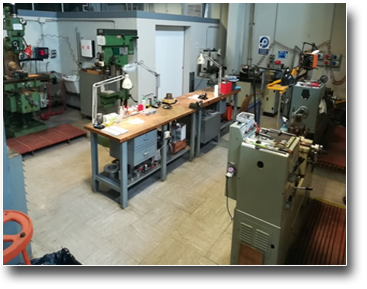

Design and fabrication of standard and advanced Vacuum Technology components and systems is extremely important for a research Institute active in introducing novel physical mechanisms and analysis technologies for materials. Although some tools are common with precision mechanics, Vacuum Technology differs in specific tools such as TIG welding, brazing, leak testing and residual gas analysis.

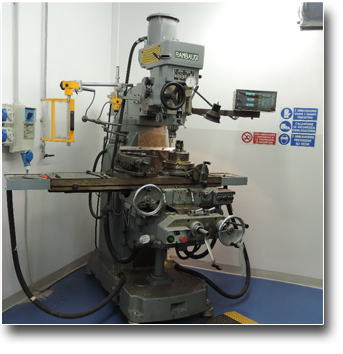

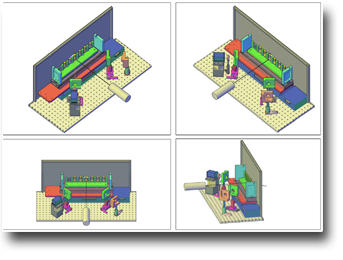

All the mechanical workshops have tools for the Vacuum Technology, however the GLAM laboratory is extremely specialized in this topic, since it provides technical support to the atomic and molecular physics group of the Elettra laboratory (Trieste, Italy) and to ISM-CNR research activities, within the MIUR International Project EUROFEL. The laboratory performs 3D design of advanced instrumentation for vacuum and ultra-high vacuum experiments. It carries out precision mechanical works at the Elettra ST workshops. It assembles and tests the new equipment as well as it takes care of the maintenance of the equipment in use at the beamlines.

Sealing and welding for vacuum systems GLAM Vacuum test GLAM

English (UK)

English (UK)  Italiano (Italia)

Italiano (Italia)